3.3.3 Solvents and Solvent Preparation

Solvent purity requirements depend on the type of samples being analyzed. All solvents used as the mobile phase must be filtered through 0.2 μm filters prior to entry to an HPLC system in order to avoid the scratching of the pump pistons by particles and to avoid clogging the in-line filter or guard column. Organic chemists are usually not concerned with the purity of solvents since their analytes are present in high concentrations and their samples usually contains many side-products and solvents. Hence, relatively low purity, and therefore inexpensive, solvents can be used. In contrast, the analytical chemist must purchase HPLC grade solvents that are considerable more expensive. For example a 20-L metal can of ACS grade methanol costs less than $70, while a 4-L glass bottle of HPLC UV-Vis grade bottle costs $150. Many solvent gradients call for acetonitrile that in recent years (2009-2009) has risen considerable in costs due to a decrease in production, from $100 in 2005 to $250 in 2009 (if supplies allow you to even order it). The increase in cost has tempted many chromatographers to switch their acetonitrile solvent gradients to one based on methanol while maintaining the same polarity index (a measure of the polarity of the solvent mixture that is used to optimize analyte separation). However, as noted by William Campbell in a recent Supelco Analytical Note (volume 27.1, page 13), while analyte retention orders may (or may not) remain the same, the relative retention times and resolution can significantly change, in some cases where analyte separations are no longer achievable. Solvents used for elution are contained in glass reservoirs (usually one liter in capacity) and connected to HPLC with Teflon tubing. The solvent bottle is purged with He gas to remove dissolved gases, mentioned above, and kept under a He atmosphere during HPLC operation.

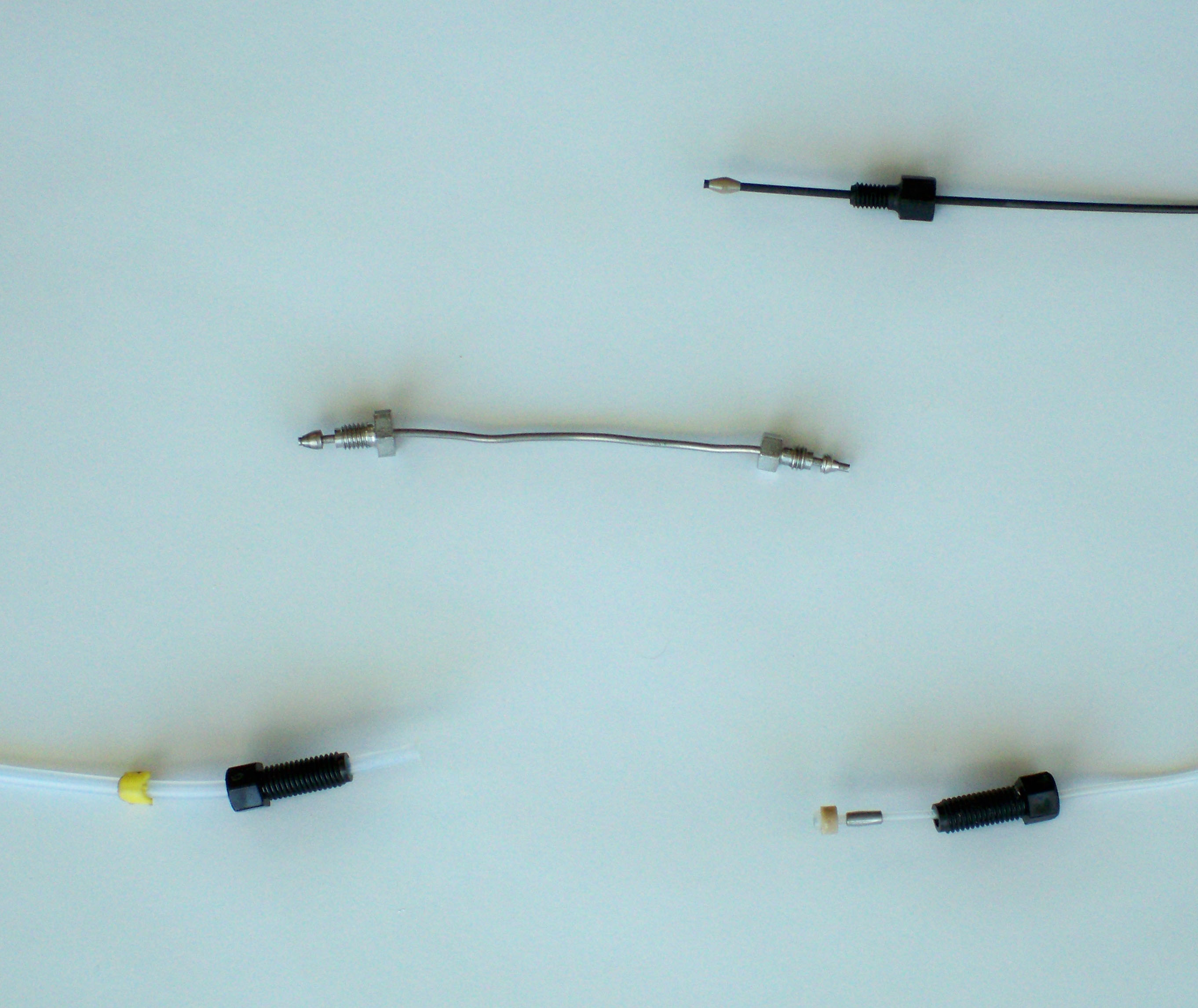

Tubing and Connections: Different components of an HPLC system operate under different pressures ranging from atmospheric to 4 500 psi (3.10 x 107 Pa) in standard HPLC and to 20 000 psi (1.38 x 108 Pa) in ultra high pressure liquid chromatography. Systems are currently under development that will operate at 100 000 psi. While GC fittings are usually standardized to Swagelok fittings, many HPLC manufactures have established their own type of high pressure fittings. All operate on the same ferrule-nut configuration as in GC but the shape of the ferrule and receiving system is different. A few of the more common fitting are shown in Figure 3.3. Tubing sizes are much smaller in HPLC as compared to GC. Common tubing materials are stainless steel and PEEK (polyaryletheretherketone), a very strong organic polymer.

Figure 3.3 A Selection of HPLC Tubing and Connectors.

©Dunnivant & Ginsbach, 2008