3.3.4 Proportioning Valve

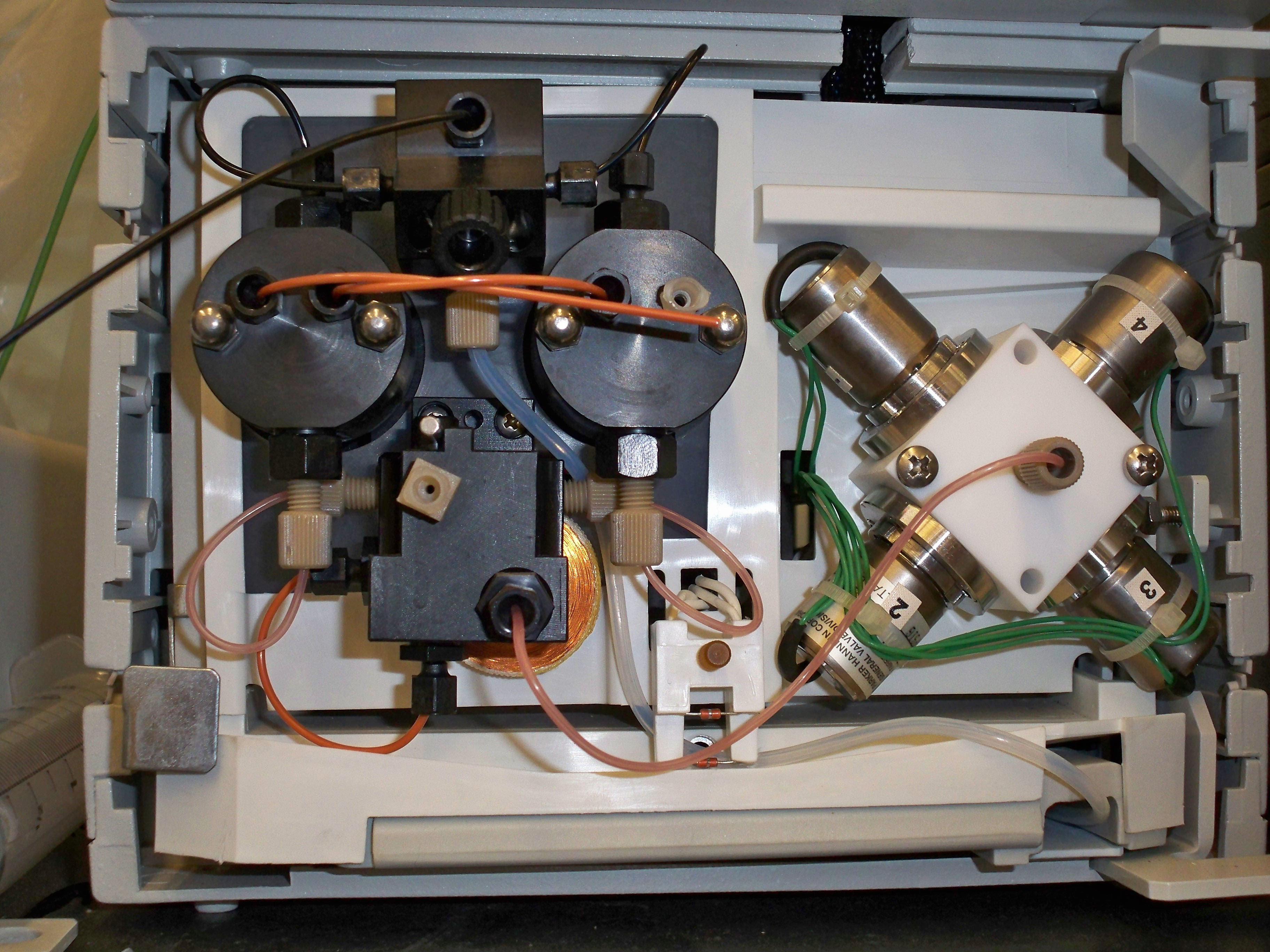

Up to four separate elution solvents enter the HPLC first through a proportioning valve that adjusts the flow of each solvent to a predetermined amount. A proportioning valve is shown in Figure 3.4. Prior to the development of the proportioning valve, a separate pumping system was needed for each solvent. Since the pumping system (Figure 3.4) is typically the most expensive component of an HPLC system, the proportioning valves help reduce the cost of an HPLC system.

Figure 3.4 A Dual Piston Reciprocating Pump (left) and a Four-Way Proportioning Valve (right).

The relatively inexpensive proportioning valve allows the mixing of up to four solvents which enter a single pumping system. The mobile phase can be delivered as a constant composition of solvents (isocratic) or as a changing composition (gradient programming). In gradient programming, the solvent composition changes from a more polar solvent mixture to a more non-polar organic composition. Isocratic operations are used for relatively simple separations, while gradient programming is used for complex separations. In the past, the relative flow rates of multiple pumps were used to control the mobile phase composition. Today the less expensive proportioning valves adjust the composition. The need for gradient programming is illustrated in Animation 3.2 and is similar to temperature programming in GC and is again referred to as the general elution problem. Click on the figure below to start the animation.

Animation 3.2 The Solution to the General Elution Problem in HPLC.

©Dunnivant & Ginsbach, 2008